The foremost advantage of producing Nitrogen and Oxygen in-house lies in its environmental significance. The elimination of truck deliveries stands as a pivotal benefit. While this may not immediately translate into direct monetary gains for users, its larger positive impact on the environment is undeniable. The cessation of truck deliveries translates to a reduction in carbon emissions—an imperative step towards combating global warming. An enlightening study conducted on behalf of one of our esteemed clients in Brampton, Ontario, revealed a startling truth. The Nitrogen delivered via tankers contributes to a staggering annual CO2 emission of 6,979.5 KG. To offset this carbon footprint as part of their Corporate Social Responsibility, they are required to plant 300 trees every year. This serves as a striking reminder that every user of Nitrogen and Oxygen sourced from external suppliers possesses the power to make a substantial contribution to carbon footprint reduction. The elimination of truck and transport deliveries becomes an embodiment of the "Go Green" initiative.

Boost Performance and Savings with OnSite Oxygen and Nitrogen Generation

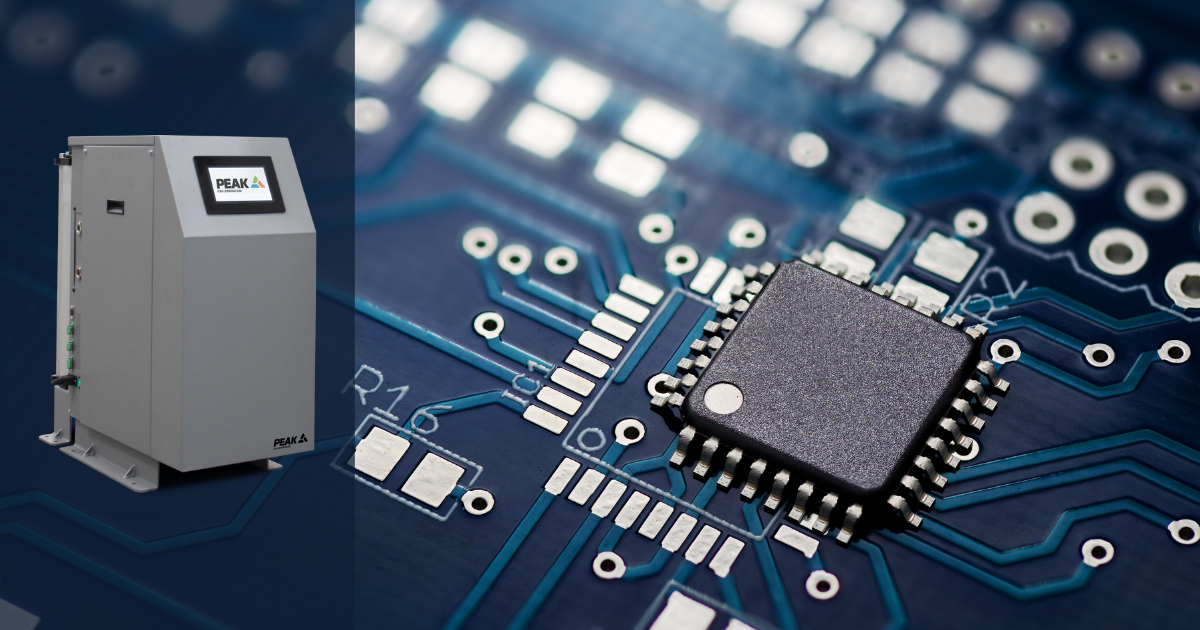

The impact of compressed air on industries globally is undeniable, spanning from small tire shops to vast oil and gas sectors, as well as specialized domains like laboratories and pharmaceuticals. Amid this industrial transformation, many have taken control by employing in-house air compressors, air dryers, and related equipment to autonomously generate compressed air. Inhouse compressed air generation eliminates the need for relying on external sources, whether through cylinder bulk packs, Dewars, or tankers delivering compressed air.

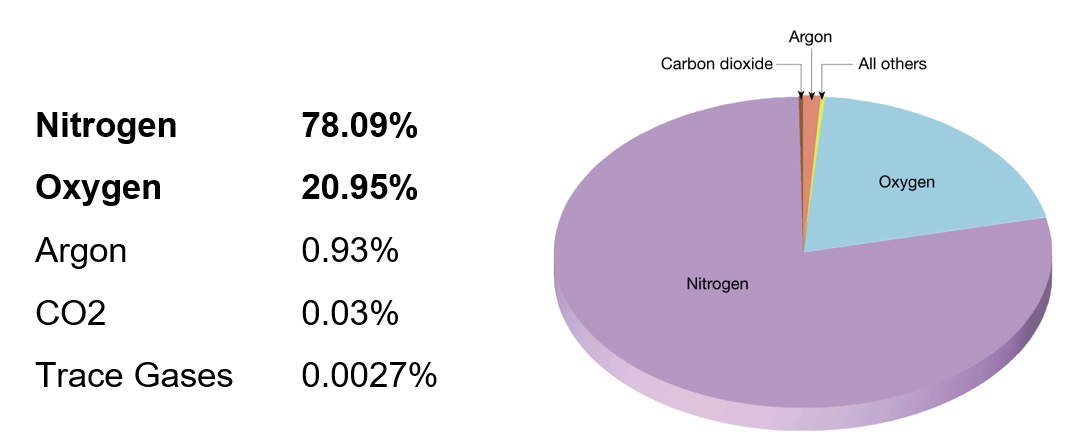

However, when the demand arises for specialized gases such as Nitrogen and Oxygen, a dependency on gas companies often prevails. In an era where humanity is achieving feats like landing spacecraft on the moon's South Pole, it's imperative to question the conventional and inefficient practice of sourcing Nitrogen and Oxygen through external gas suppliers. Remarkably, our atmosphere contains an abundant supply of two pivotal gases: Nitrogen, constituting 78.09%, and Oxygen, comprising 20.95%.

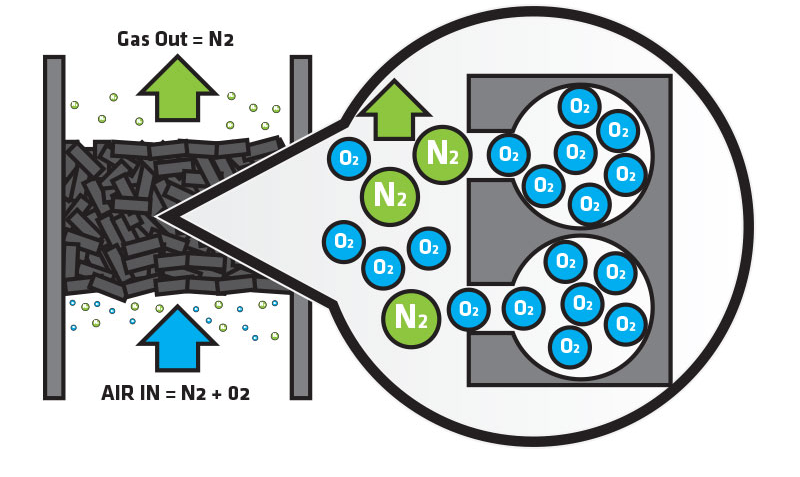

When an air compressor is in operation, it draws air from the surrounding atmosphere, compresses it, and then delivers it under pressure to meet specific needs. This compressed air is a mixture of various gases, including Nitrogen (N2), Oxygen (O2), and other components. To put it simply, if a customer requires Nitrogen, an Oxygen filter is necessary. Conversely, if the process demands Oxygen, a Nitrogen filter should be added to the line. This adaptation ensures the fulfillment of both Nitrogen and Oxygen requirements. These filters are commonly referred to as Nitrogen Generators and Oxygen Generators. The image below provides a straightforward depiction of an Oxygen Filtration system.

Regarding on-site Nitrogen generation, there are two primary categories available:

- Pressure Swing Adsorption (PSA) Nitrogen Plant / Generator

- Membrane Nitrogen Generator

Similarly, for on-site Oxygen generation, two primary types are prevalent:

- Pressure Swing Adsorption (PSA) Oxygen Plant / Generator

- Vacuum Pressure Swing Adsorption (VPSA) Oxygen Plant / Generator

Let's now delve deeper into the extensive benefits of on-site Nitrogen and Oxygen Generation.

1. Environmental Advantage

2. Cost Savings

Another significant advantage of on-site Nitrogen and Oxygen Generation lies in the realm of cost efficiency. This advantage is magnified through the production of Nitrogen and Oxygen gases within your own premises, obviating the reliance on external suppliers. This strategic transformation has the potential to yield substantial savings for your organization. Transitioning towards in-house production of Nitrogen and Oxygen can trigger a noteworthy reduction in costs.

To provide a tangible perspective, let's consider the pricing dynamics. A Nitrogen gas supplier typically charges around 50 cents per cubic meter (m3), and this doesn't even encompass ancillary expenses like tank rentals and duties. In sharp contrast, producing Nitrogen in-house can be achieved at approximately 6 cents per m3, leading to remarkable savings. While the cost of producing on-site Oxygen slightly exceeds that of Nitrogen, around 18 cents per m3, it still presents a significant reduction compared to purchasing from external suppliers. This substantial cost differential underscores the compelling financial rationale behind on-site gas generation.

3. Price Stability

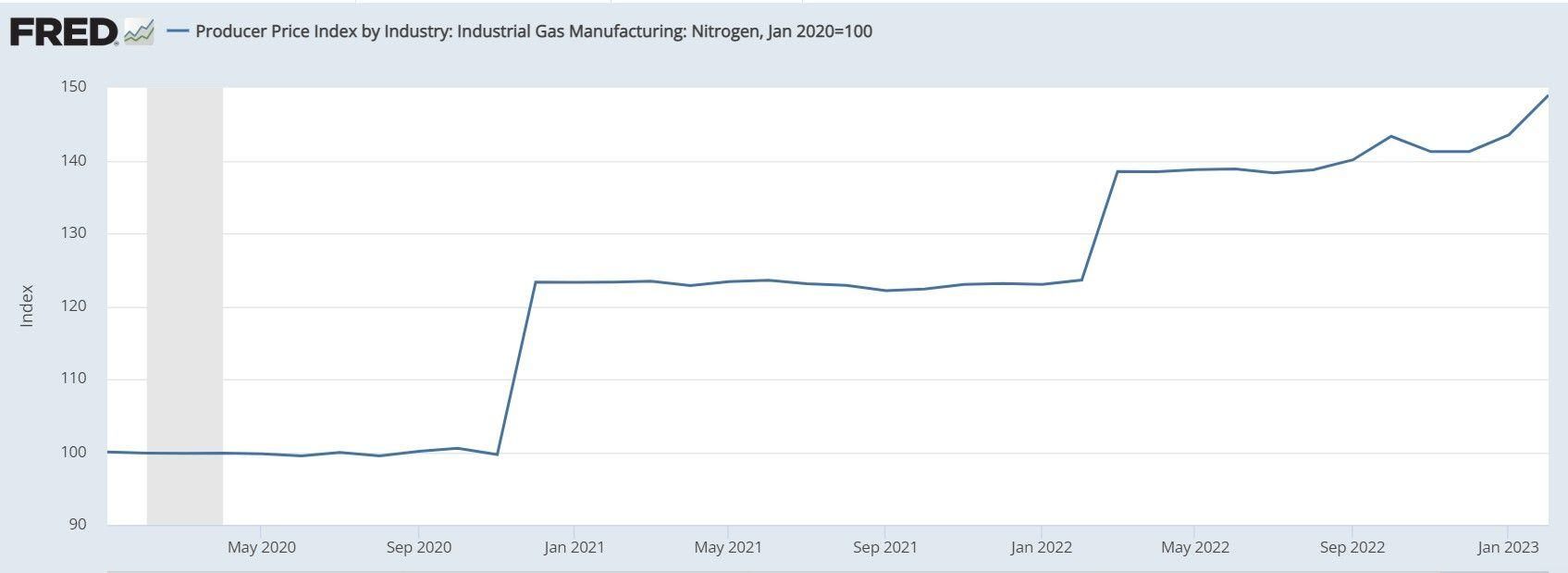

Shield yourself from fluctuating prices. Moreover, by embracing this approach, users can shield themselves from the risks associated with price escalations. The recent trajectory, as indicated by the U.S. Bureau of Labor Statistics, has been rather unsettling. Over the past three years, the Producer Price Index of Industrial Nitrogen Gas has surged by nearly 50% starting from January 2020.

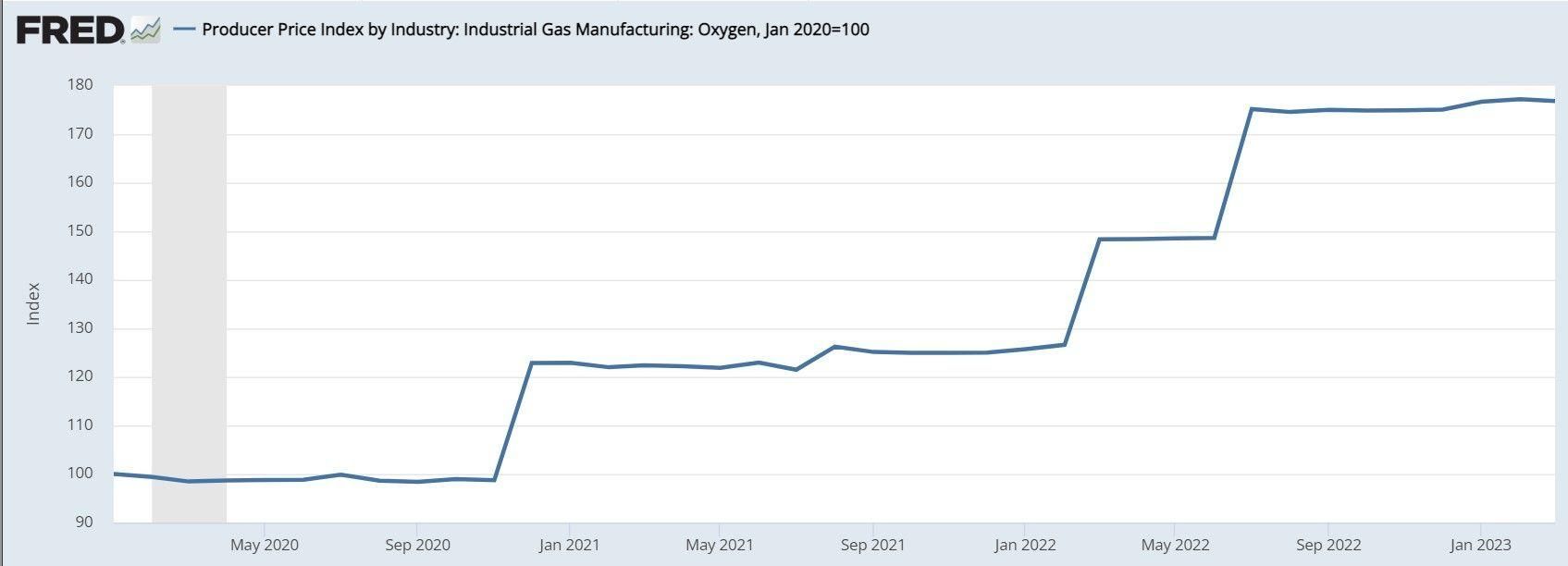

Remarkably, the situation is even more concerning in the realm of industrial Oxygen gas pricing. Over the same three-year span, the Producer Price Index recorded an astonishing 80% increase. These steep and consistent price hikes underscore the volatility and uncertainty inherent in relying on external suppliers. On the contrary, on-site generation empowers businesses to escape this price rollercoaster and establish more predictable and favorable cost structures.

4. Enhanced Safety

There are three prevalent methods for delivering Nitrogen and Oxygen: Gas Cylinders, Dewars, and Bulk Liquid Tanks. The inherent risks tied to these transported gases are visually evident in the images below.

- Gas Cylinder: Delivered at high pressure (200 – 300 BarG).

- Dewar: Delivered in a liquid state.

- Bulk Liquid: Transported as cryogenic Nitrogen or Oxygen in liquid form.

These delivery methods bring forth substantial safety concerns associated with Nitrogen and Oxygen. Navigating these gases demands heightened precautions upon their arrival. A particularly hazardous aspect arises when liquid Nitrogen transforms into its gaseous state, expanding nearly 700 times and generating formidable force upon vaporization. Rapid freezing can lead to dire consequences, including frostbite or worse. The lack of proper ventilation during swift liquid Nitrogen release could even escalate asphyxiation risks.

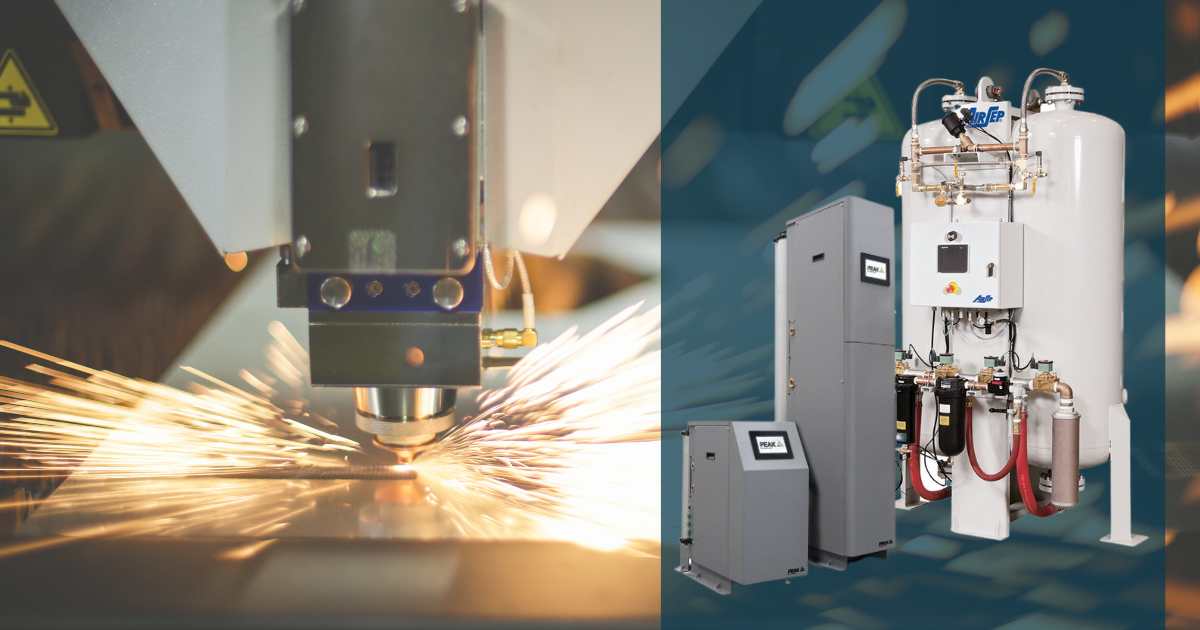

These complexities and dangers can be sidestepped by initiating in-house generation of Nitrogen and Oxygen. The installation of a Nitrogen/Oxygen Generator presents a straightforward process that eliminates all perils related to transportation. Moreover, the transition from purchasing Nitrogen and Oxygen in liquid form to producing them in their gaseous state in-house not only mitigates risk but also poses a critical question: Why opt for the liquid form when the gas form suffices for your needs? Below is an image depicting a Simple Generator installation in Ontario, Canada.

5. On-Demand Generation

Onsite generation eliminates the Supply Chain challenges. The world suffered catastrophic losses during the Covid 19 pandemic and companies struggled to fulfill the soaring demand for Oxygen across various regions. It was during these trying times that in-house Oxygen generators emerged as saviors, bridging the gap for countless users. Unlike those reliant on external suppliers and waiting for gas deliveries, generator users experienced uninterrupted access.

Whether your gas (N2 and O2) demands are constant or intermittent, an in-house generation system tailors itself to your needs. The system adapts, ensuring that a continuous supply of gas is readily available whenever required. This flexibility not only bolsters operational resilience but also underscores the autonomy and reliability that on-site generation brings to your business.

6. Say No To Contracts (Flexibility and Freedom)

The majority of customers find themselves obligated to sign intricate legal contracts when procuring gas from external suppliers. These contracts often contain complex clauses, making it challenging for users to grasp the potential consequences of non-compliance. The beauty of on-site generators lies in the unfettered flexibility they offer. They eliminate the need for binding contracts, enabling users to seamlessly initiate the in-house production of Nitrogen and Oxygen without the constraints of legal agreements. This liberation empowers businesses with the autonomy to shape their gas production strategy as needed, unburdened by contractual intricacies.

In conclusion, it's time to harness the abundance of Nitrogen and Oxygen that nature provides. By embracing on-site generation of these gases, industries can not only enhance their operational efficiency but also contribute to a greener planet. The opportunities are vast, from cost savings and environmental preservation to seamless accessibility and enhanced safety. The time has come to harness the resources around us and take charge of our own Nitrogen and Oxygen needs, transcending the limitations of traditional supply chains. Start producing in-house and unlock a new era of performance and savings.

Share This Article With Your Network