Gas Purity Solutions

Control Your Gas Supply, Protect Your Operations

When gas purity is critical to your operations, relying on delivered cylinders or bulk supply exposes you to unnecessary risks. Without real-time control, even a small impurity can compromise your processes, damage your reputation, and cause costly downtime. Specialty Gas gives you back control with customized on-site nitrogen and oxygen generation systems—designed to deliver consistent, verified purity at the exact standards your industry demands.

With Specialty Gas, your gas quality is no longer a gamble. It's a guarantee.

What Is Gas Purity?

Gas purity refers to the concentration of a specific gas, like nitrogen or oxygen, compared to unwanted contaminants or particles. For example, when a client requests nitrogen gas, purity defines how much of the produced volume is pure nitrogen versus other gases like oxygen. A system producing 99.9% nitrogen purity means that 0.1% consists of residual gases. In ultra-high purity applications, like "five nines" nitrogen (99.999%), only 10 parts per million are contaminants.

At Specialty Gas, we design generation systems that consistently deliver the purity levels your specific industry needs—not more, not less—ensuring both operational excellence and cost efficiency.

Why Gas Purity Matters for Your Operations

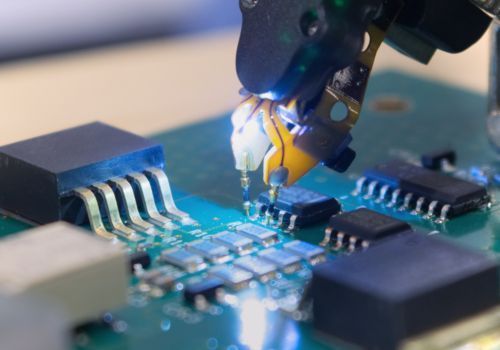

Gas purity is one of the most important factors considered when we design a system. Every business has different requirements based on their application. For example, in food packaging, maintaining low oxygen levels is critical for product shelf life, while electronics manufacturing demands ultra-pure nitrogen to avoid oxidation during soldering processes.

Using impure gases can have serious consequences. In food applications, poor purity can dramatically shorten the shelf life of products, leading to recalls and brand damage. In manufacturing, impurities can cause product defects or quality failures, resulting in costly returns and reputational harm. Quality matters—and in today’s competitive environment, there’s no room for compromise.

Common Misconceptions About Gas Purity

One of the most common misconceptions is that clients assume they always need the highest possible purity, such as "five nines" (99.999%) nitrogen. In reality, different industries and applications have very different purity needs. Overspecifying purity not only increases system cost but also energy consumption. At Specialty Gas, we work closely with clients to determine the optimal gas purity for their operations, avoiding overinvestment while maintaining product quality.

How We Determine the Right Purity for Your Business

Our recommendations are based on decades of hands-on industry experience, combined with constant learning. Our team regularly attends industry-specific exhibitions and trade shows, staying current with the latest technological and process trends. This ongoing field experience, paired with direct client collaboration, ensures that every system is matched to your real-world needs.

How We Guarantee and Maintain Gas Purity

Unlike traditional gas delivery, where purity is assumed and verified only after production problems occur, Specialty Gas systems provide:

- Real-Time Monitoring: You can see the purity level on the system interface at any time.

- Automatic Alarms and Failsafe Protection: If the purity drops below your set threshold, alarms will activate and the system will stop production to prevent impure gas from entering your process.

- Built-in Minimum Purity Assurance: Systems are configured so that the promised purity, such as 99% or 99.9%—is the minimum delivered. If purity falls, the system alerts you immediately.

During installation, our in-house team, supported by factory-trained startup technicians, conducts a complete commissioning process to verify all operating parameters, including purity. Preventive maintenance programs are also implemented, including regular purity testing, detailed site visit reports, and recommendations for keeping your system in peak condition.

Why On-Site Gas Generation Beats Cylinder Delivery

Choosing on-site gas generation gives your business major advantages:

- Full Control: Real-time verification of purity without relying on external suppliers.

- Cost Savings: Reduce the cost of oxygen or nitrogen gas costs by up to 90% compared to cylinder delivery.

- Operational Continuity: No supply chain risks, no waiting for refills.

- Sustainability: Reduce your carbon footprint by eliminating transportation emissions.

With a Specialty Gas Canada system, you are in command of your gas quality and supply every day.

Industries We Serve

Gas purity impacts almost every industry. Specialty Gas systems are designed to meet the diverse needs of sectors such as:

Food and Beverages

Modified Atmosphere Packaging (MAP) to protect shelf life.

Electronics Manufacturing

High-purity nitrogen for selective soldering processes.

Laser Cutting

Stable nitrogen or oxygen supply for high-precision material cutting.

Pharmaceutical and Biotech

Controlled atmospheres for sensitive production processes.

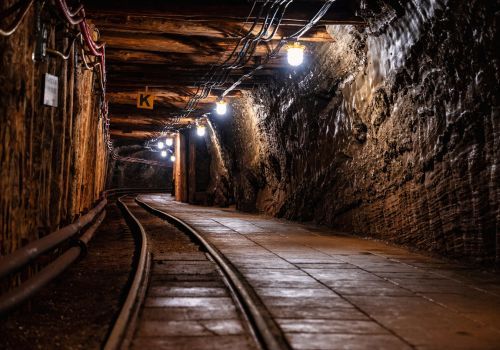

Oil and Gas

Nitrogen inerting for safety and operational reliability.

Mining

Oxygen systems designed for efficient gold leaching and reduced chemical use.

Aquaculture

Oxygen generation systems that support water quality, fish density, and disease prevention.

Heat Treatment

Nitrogen and oxygen purity ensure repeatable results in controlled atmospheres.

Metal Fabrication

Reliable gas supply for coating integrity and material performance.

Glass and Ceramics

Oxygen stabilization for clean combustion and consistent product quality.

Wastewater Treatment

High-purity oxygen to support aerobic digestion and meet environmental standards.

Brewing and Beverage Packaging

Nitrogen systems that protect flavour and prevent oxidation during bottling and canning.

No matter the industry, gas purity is a crucial operational requirement, and our systems are engineered to meet it.

From Consultation to Continuous Support

We take ownership of every stage of the project:

- Consultation and Site Evaluation: We assess your gas needs, process applications, and potential financial incentives.

- System Engineering and Proposal: Designs are customized based on your operations, backed by ROI calculations.

- Installation and Startup: Factory-trained technicians perform all installation and commissioning steps.

- Training and Handover: Your team is trained to monitor and manage gas generation systems confidently.

- Ongoing Service and Reporting: Preventive maintenance plans, purity reporting, and system optimizations ensure long-term reliability.

Every one of our customer relationships is built on proactive support and transparent service.

Certifications and Compliance Standards

Specialty Gas systems are built to comply with stringent industry standards, including:

- CSA certifications for equipment safety

- CRN approvals for high-pressure system compliance in Canada

- Electrical approvals for industrial system installation

- Food Grade Certifications for nitrogen generation systems used in food production environments

Although our systems are not certified for direct medical oxygen use in Canada, they meet stringent oxygen purity certifications for industrial and international applications in the healthcare sector.

Specialty Gas Canada for Your Gas Purity Needs

Choosing Specialty Gas means choosing reliability, expertise, and real control over your gas supply. Our focus is not just delivering equipment—but delivering confidence. We understand that in industries like manufacturing, food processing, and electronics, gas purity is mission-critical. That's why every system we install is designed to perform, protect, and pay off from day one.