Stop Guessing Your Gas Usage: Demand Analysis for Nitrogen and Oxygen Systems

Get real usage data, eliminate waste, and build a gas system that fits your actual needs.

Most facilities track how many nitrogen or oxygen tanks they order, but few know how much gas they actually use, where it's wasted, or how much they’ll need as operations change.

That’s where Specialty Gas comes in.

A professional demand analysis uses real-time monitoring to measure gas usage, identify inefficiencies, and help you make smart, cost-saving decisions. Whether you’re expanding production or cutting overhead, this is the first step toward a system that works for your business—not against it.

What Is a Demand Analysis?

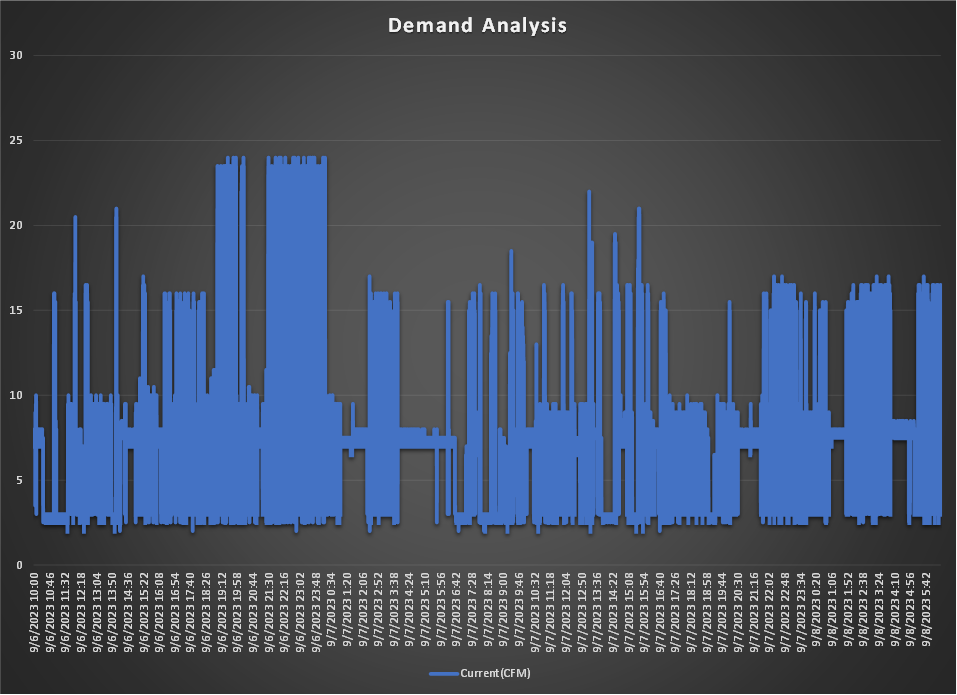

A nitrogen or oxygen demand analysis involves placing a monitoring kit at key points in your system. Over the course of a week, it records gas usage patterns across your facility—during production, idle times, and overnight.

You’ll receive data on:

- Peak, average, and minimum gas demand

- Leaks or usage during downtime

- Whether your system is oversized or undersized

This is real operational data, not estimates or assumptions.

Why Most Facilities Are Overspending

Gas waste often goes unnoticed. A stuck valve or a small leak could be draining thousands of dollars per year.

One manufacturer saved over $7,000 annually by fixing a faulty valve identified through demand analysis. Another discovered that the equipment was consuming nitrogen during employee breaks.

These aren’t rare issues; they’re common inefficiencies we see all the time.

No Usage History? No Problem.

Even if you haven’t started production yet, Specialty Gas can still help.

Our team has years of industry-specific experience and access to OEM gas usage data for equipment like MAP packaging lines and selective soldering units. For newer or custom machines, we’ll work directly with your supplier to get accurate estimates.

That means you can still get a right-sized system—even before installation.

Minimal Disruption to Your Operation

Concerned about downtime? Don’t be. In most cases, demand analysis kits are installed without interrupting your daily workflow.

Specialty Gas performs a feasibility walkthrough first to identify ideal connection points and minimize interference. If a brief shutdown is needed, we work with your schedule—often installing during off-hours or weekends to avoid production delays.

This means you get the data you need without unnecessary disruptions.

A Report That Leads to Real Decisions

Once the data is collected, you receive a concise, actionable report that includes:

- Flow and pressure graphs

- Insights into waste and inefficiency

- Right-sized system recommendations

- Adjustments for seasonality and growth

No jargon. No guesswork.

Growth and Seasonality Factored In

Your nitrogen or oxygen usage may not be consistent year-round. If your facility scales output during certain seasons or you’re planning to add new equipment, Specialty Gas builds that into your demand profile.

For example, if your summer production jumps 30% over winter, we will adjust the system recommendation accordingly. If your demand shifts are significant, we may even suggest a second demand analysis during your peak or off-season to get the full picture.

You don’t just get a snapshot of today. You get a roadmap for what’s coming.

The No-Risk Guarantee

Specialty Gas stands behind every demand analysis we perform.

If the ROI from the study is less than what you paid for it, you don’t pay. And if you move forward with our system recommendation, we’ll credit the full cost of the analysis toward your purchase.

There’s no financial risk—only clarity, savings, and peace of mind.

Move Forward with Clarity

This isn’t about charts. It’s about confidence:

- Know what you use

- Fix what’s wasting money

- Plan what you’ll need next

With a nitrogen demand analysis or oxygen demand analysis from Specialty Gas, you'll finally have the insight and confidence to move forward.

Ready to find out what your system really needs?

Contact Specialty Gas today to schedule your demand analysis and take the first step toward reducing waste, improving efficiency, and preparing your facility for what's next.

FAQs

What is a nitrogen or oxygen demand analysis?

A demand analysis measures how much nitrogen or oxygen your facility actually uses—minute by minute—so you can spot inefficiencies, leaks, or overuse and make smarter system decisions.

Who should get a demand analysis?

Any operation using nitrogen or oxygen, especially those seeing rising gas costs, adding equipment, or unsure of actual usage can benefit. It’s also ideal for new facilities planning their first system.

Will the demand analysis disrupt our production?

In 90% of cases, No. Specialty Gas installs the monitoring kit without shutting anything down. If access is needed, it’s scheduled around your least busy hours to avoid disruption.

What if my gas usage changes seasonally?

Specialty Gas factors in seasonal swings during analysis. If your demand changes significantly, we may recommend a second study during peak or low season to design a system that fits year-round.

What does the guarantee actually cover?

If the ROI from the analysis is less than what you paid, the study is free. And if you move ahead with their system recommendation, you get the full cost of the study credited to your purchase.