Nitrogen and Oxygen Systems Engineering Design

Discover how Specialty Gas delivers engineered nitrogen and oxygen systems designed around your facility's exact requirements—backed by local service, expert advice, and complete project support.

Built Around the Client: Specialty Gas Custom Approach

Specialty Gas provides nitrogen and oxygen generation systems that are purpose-built to meet your exact operational requirements. Every project begins with a customer-centric consultation—your process, your priorities, your performance standards. We are not here to sell a product off the shelf. We design and install solutions tailored to your facility and application.

If a customer sends full technical specifications, great. If not, we send a detailed nitrogen or oxygen qualification worksheet. If you need help, our team walks through it with you. That’s our approach to support—personal, responsive, and precise.

By working alongside the expert engineering teams at Peak Scientific and AirSep, we guarantee a technically robust solution tailored to your needs. You receive a customized proposal, including ROI calculation and government funding opportunities. We then walk you through the solution to make sure every detail aligns with your expectations before we install the system.

Engineering Systems for Your Actual Environment

No two plants are the same. That’s why Specialty Gas engineers every nitrogen and oxygen system to your facility’s exact specifications—accounting for layout, equipment, and operational demands. Whether you're located in Canada, the USA, Africa, or anywhere else in the world, we deliver solutions that meet your regional standards and your team's performance expectations.

We design around your voltage, frequency, and utility availability. Our engineering team also considers your growth plan so that the system can scale as your demand increases. We offer remote support or we can dispatch technicians directly to your facility.

Custom vs. Standard: Which One Do You Need?

We offer both standard and custom-built systems. A standard unit works well for smaller applications, like fish farming or basic lab setups. However, if your operation has variable loads, high demand, or future growth planned, a custom gas system is the only logical choice.

For example, when a customer needed to fill 60 oxygen cylinders daily, we built a fully engineered system tailored to space, purity, and flow requirements. Whether you need a containerized, skid-mounted, or modular design, we can deliver a turnkey solution that’s right for you.

Engineering Principles That Deliver Results

We ask the right questions, even if they’re difficult or repetitive. Every gas system is designed based on operational specifics, including:

- Required gas composition and flow rate

- Available voltage and utility specs

- Shift schedules and operating hours

- Growth projections and expansion potential

- Compliance with safety and regulatory standards

Each system is engineered independently. We never duplicate prior designs unless the applications match perfectly. That’s how we ensure high efficiency and long-term performance.

What Goes Wrong in Poorly Designed Systems?

The most common failure point? Misunderstanding what the customer actually needs.

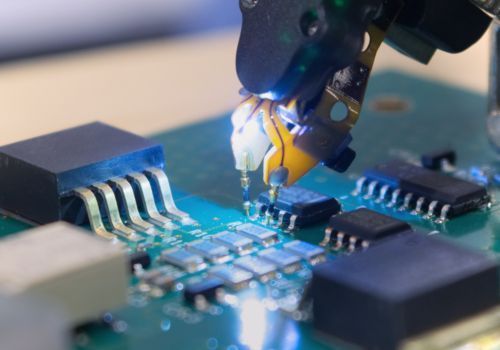

In one case, a global supplier delivered a nitrogen system to restaurants in the Bahamas. The system constantly ran out of gas because it couldn’t handle the demand. In another, an electronics plant received a nitrogen system designed for wave soldering, not selective soldering. This resulted in Dross, Solder joint oxidation, field failures, excessive energy costs, and maintenance issues. Even small purity deviations (e.g., from 99.999% to 99.9%) can drastically reduce yields in high-precision processes.

Overdesign is just as bad as underdesign. Specialty Gas avoids both by fully aligning our designs with your application and your usage profile.

Industries That Require Custom Builds

Electronics & Semiconductor Manufacturing

Electronics manufacturing demands ultra-high purity nitrogen to prevent oxidation during sensitive processes like: Wave soldering, Reflow ovens, Selective Soldering & Wafer and chip production. Custom systems ensure compatibility with cleanroom standards and deliver consistent purity for 24/7 operations.

Food & Beverage

Nitrogen is widely used in: Modified Atmosphere Packaging (MAP), Bottle flushing & Storage blanketing. Custom systems are designed around production speed, packaging types, and hygiene protocols, ensuring freshness and regulatory compliance.

Pharmaceutical & Biotechnology

From lyophilization to fermentation tanks, nitrogen ensures sterility and protects sensitive products. Custom systems are often required to meet: GMP standards, Cleanroom integration and Precise flow and control automation.

Oil & Gas / Petrochemical

In this high-stakes industry, nitrogen is used for: Pipeline purging, Tank blanketing and Leak testing and pressure control systems are custom-built for high-flow, high-pressure applications and often designed for hazardous locations (ATEX-rated).

Automotive & Metal Fabrication

Applications include: Laser cutting, Inert welding and Heat treating and annealing

This industry requires precision. All of our systems for laser cutting are custom designed based on machine kW, cutting material, and operating hours.

Chemical Manufacturing

Nitrogen is critical in preventing unwanted reactions by: Inerting reactors, Blanketing volatile chemicals and Pressurizing transfer systems. These systems must integrate with plant automation, ensure chemical compatibility, and operate reliably under extreme conditions.

Agriculture & Controlled Atmosphere Storage

Grain silos, greenhouses, and cold storage units use nitrogen to: Prevent spoilage, Control humidity and Create pest-free environments. These systems are designed for variable seasonal demand and rugged outdoor use.

Museums, Archives, and Libraries

Museums and libraries have highly specialized needs: Fire Prevention, Humidity and Moisture Control, Pest Control (Anoxic Disinfestation) and Inert Atmosphere for Preservation. A custom nitrogen system allows for precision, reliability, and non-intrusive operation in these sensitive environments.

Cylinder Filling Stations (Onsite Nitrogen & Oxygen Bottling)

Many facilities require a custom nitrogen or oxygen cylinder filling system to support flexible and decentralized gas usage. These setups are ideal for industries that: have multiple remote points of use, Require backup gas storage, hospitals and need to fill different sizes of cylinders for internal or third-party use

Scalable Manufacturing

If your company is growing, you need a nitrogen or oxygen system that scales with you. We account for future expansion from day one.

Standard Applications

For labs and fish farms, standard units often suffice. We still assess each application to confirm it's the right fit before installation.

Why Our Local Support Matters

We are based in Ontario with a large network of trained technicians ready to respond quickly. Unlike big gas corporations, we don’t push a fixed product line. We choose the best nitrogen or oxygen system based on your needs and integrate it with a compressed air system when required.

You get a dedicated solutions expert and two technicians who understand your facility and are available for regular service. That’s what we mean by responsive, local support.

Compliance Is Not Optional

Each installation is reviewed for jurisdictional compliance. Whether you need CRN certification, CSA approval, CE Certification, or ASME standards, we handle it. Our designs account for regional, national, and international codes.

Maintenance that Fits Your Operation

Every Specialty Gas system includes onboard notifications when maintenance is due. We tailor your service plan to your operating schedule—whether you run one shift or 24/7.

Our proactive maintenance ensures system reliability, helps avoid downtime, and extends equipment life. It’s just one more reason our clients stick with us.